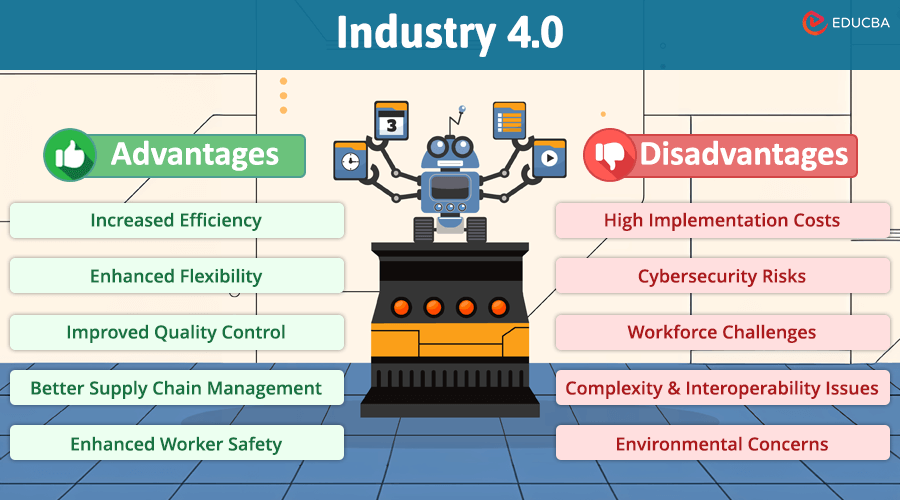

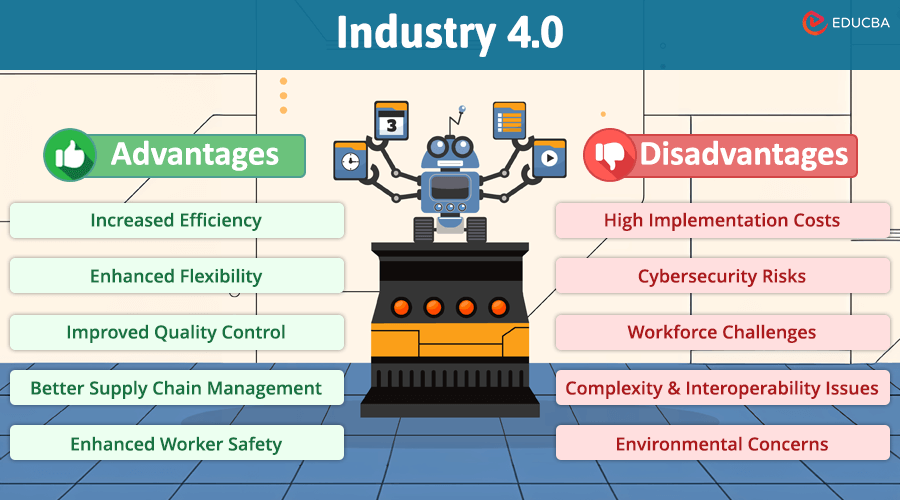

Understanding Advantages and Disadvantages of Industry 4.0

Industry 4.0 refers to the fourth major revolution in manufacturing. It involves using new technologies such as smart machines, the Internet of Things (IoT), artificial intelligence (AI), and robotics to make factories work better and adapt more easily. In this article, we will look at the advantages and disadvantages of Industry 4.0 to get a clear picture of what it means for the manufacturing sector.

Advantages of Industry 4.0

The advantages of Industry 4.0 are:

1. Increased Efficiency

Industry 4.0 technologies significantly enhance manufacturing efficiency by automating repetitive tasks and optimizing processes. Automation reduces the need for human labor, lowers the chance of mistakes, and speeds up production.

Additionally, real-time data collected through IoT devices allows for immediate adjustments to the production process, further boosting efficiency. This continuous data stream enables manufacturers to fine-tune operations and address issues proactively, leading to reduced operational costs and improved productivity.

2. Enhanced Flexibility

The ability of Industry 4.0 technologies to adapt to new production requirements is a game-changer for flexibility in manufacturing. Smart systems can quickly reconfigure production lines to accommodate different products or changes in demand without significant downtime. This adaptability facilitates mass customization, allowing manufacturers to offer various products tailored to individual customer preferences. Moreover, these technologies support scalable operations, making it easier for manufacturers to adjust their production capacity in response to market fluctuations.

3. Improved Quality Control

Industry 4.0 enhances quality control through advanced predictive maintenance and precise automation. AI and machine learning algorithms can predict equipment failures before they occur, minimizing downtime and maintaining consistent product quality. This proactive approach ensures that machinery operates optimally, reducing the likelihood of defects. Additionally, advanced robotics and automation increase the precision and accuracy of manufacturing processes, resulting in higher-quality products and fewer errors.

4. Better Supply Chain Management

Integrating digital technologies in Industry 4.0 transforms supply chain management by providing greater transparency and efficiency. Blockchain and other digital tools enhance traceability, ensuring that products are authentic and reducing the risk of fraud. Real-time tracking systems let manufacturers monitor goods as they move through the supply chain, helping streamline operations and reduce lead times. These improvements lead to more efficient inventory management and lower costs, benefiting manufacturers and consumers.

5. Enhanced Worker Safety

Automating hazardous tasks and implementing real-time monitoring systems improve worker safety in Industry 4.0 environments. Automating dangerous tasks greatly reduces the risk of accidents and injuries on the factory floor. Additionally, wearable devices and IoT sensors monitor workers’ health and safety, providing real-time alerts if hazardous conditions are detected. This proactive approach helps prevent accidents and ensures a safer working environment.

Disadvantages of Industry 4.0

The disadvantages of Industry 4.0 are:

1. High Implementation Costs

The transition to Industry 4.0 involves substantial initial investment in new technologies, equipment, and infrastructure. These upfront costs can be a barrier for many manufacturers, especially smaller businesses with limited budgets. Furthermore, ongoing maintenance and updates of advanced systems add to the overall expense.

Even though the long-term gains in efficiency and productivity can make up for these costs, the upfront financial burden of adopting Industry 4.0 technologies is still a major concern.

2. Cybersecurity Risks

As manufacturing systems become more interconnected, they face increased cybersecurity risks. The reliance on digital technologies and networks makes these systems vulnerable to cyberattacks, potentially leading to data breaches and operational disruptions. Ensuring robust cybersecurity measures is crucial to protecting sensitive information and maintaining the integrity of manufacturing operations. Additionally, compliance with data privacy regulations adds another layer of complexity in safeguarding data.

3. Workforce Challenges

The shift to smart manufacturing creates challenges for the workforce, particularly regarding skill gaps and job displacement. The advanced technologies of Industry 4.0 require a workforce with specialized technical skills, leading to a need for extensive training and upskilling programs. Furthermore, the automation of repetitive and manual tasks may displace workers, leading to potential job losses. Addressing these workforce challenges is essential for a smooth transition to Industry 4.0.

4. Complexity and Interoperability Issues

Integrating Industry 4.0 technologies with existing systems presents significant complexity and interoperability challenges. Manufacturers must navigate the technical difficulties of ensuring that new technologies work seamlessly with legacy systems. Additionally, reliance on various systems and devices can create integration issues, making smooth and coordinated operations difficult. Overcoming these challenges requires careful planning and technical expertise.

5. Environmental Concerns

Industry 4.0 also raises environmental concerns related to resource consumption and energy usage. The production and disposal of advanced technologies can have a significant environmental impact, necessitating sustainable practices and recycling initiatives. Increased automation and digitalization may lead to higher energy consumption, highlighting the need for energy-efficient technologies. Addressing these environmental concerns is crucial for minimizing the ecological footprint of Industry 4.0.

Final Thoughts

Industry 4.0 brings many benefits, like better efficiency, flexibility, quality control, supply chain management, and worker safety. However, it also has challenges such as high costs, cybersecurity risks, workforce issues, complexity, and environmental effects. Knowing these factors is important for businesses considering adopting Industry 4.0 and for policymakers creating supportive guidelines. For a closer look at how robotics enhances manufacturing efficiency and precision, check out the study “Improvement of Maintenance Management through Lean Philosophy and Industry 4.0” on Extrica.

Recommended Articles

If you found these advantages and disadvantages of Industry 4.0 informative, check similar articles.